Services

We offer services in the areas of research and development, custom manufacturing and analytical activities through our own laboratory.

Custom research and development

Custom production

Analytical activities

Details

Custom research and development

We support our customers in developing new materials and fabric laminates comprising nanofibers. We prepare samples according to specification with required technical parameters. We use our own know-how in the development of products for our customers.We have these devices for the realization of research and development:

- Laboratorní stroj pro výrobu nanovláken NS1WS500U umožňuje přípravu nanovlákenných materiálů z organických polymerů na různé substráty v šíři materiálu 300- 500 mm. Zřízení umožňuje výrobu vzorků v jednotkách centimetrů čtverečných až jednotky metrů čtverečných. Zařízení umožňuje rychlou a efektivní výrobu vzorků s nízkými provozními náklady a s potřebou materiálu.

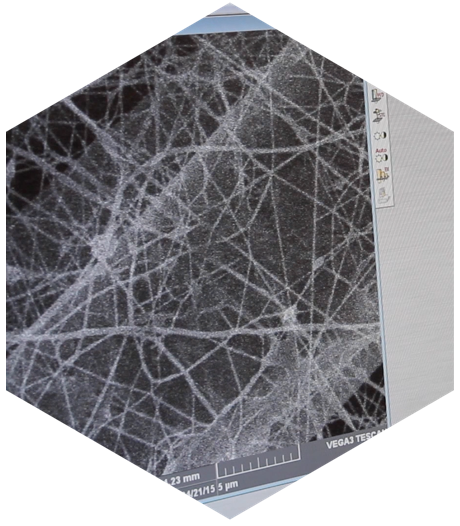

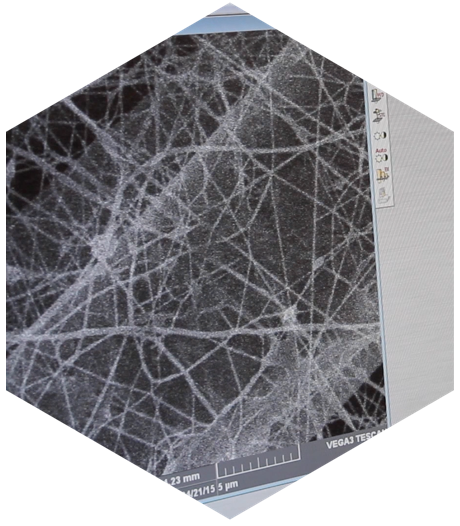

- Scanning electron microscope VEGA 3 SEM enables monitoring of nanofiber layers and evaluation of the fibre diameters.

- ARDMEL Hydrotester MK2 enables measuring the resistance of a material against water column

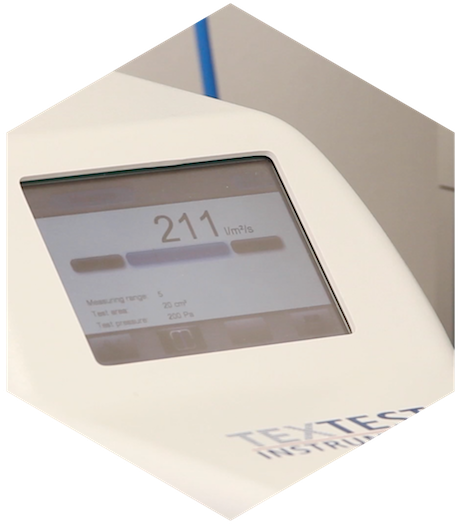

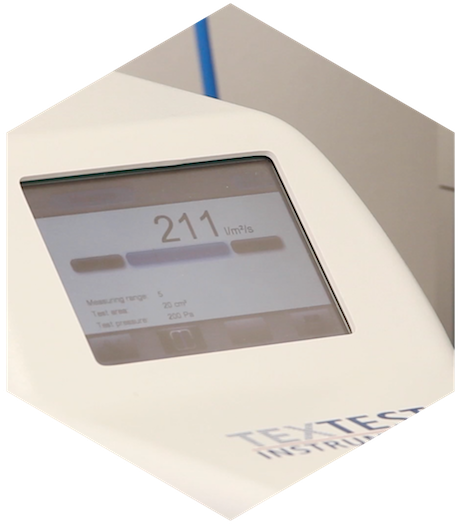

- TEXTES FX 3300 device for measuring permeability and pressure drop

- TOPAS PSM 165 FS device used to evaluate the porosity of the nanofiber layer and measure the bubble point value

- Automatic filter tester TSI CertiTest® 8127 – for testing respirators (EN 143) and filter media

- PALAS MFP, 2000 – device for evaluation of fractional filter efficiency of filter materials and media (EN 779).

If you are interested in using our services in the development of materials with nanofibers, please send your inquiry to the email address: 49054905@seznam.cz

Custom production

Nanovia s.r.o. offers a production of nanofiber materials from organic polymers according to customer requirements. Nanofiber materials from various polymers can be deposited onto various substrates.Custom manufacturing is usually preceded by optimization of the manufacturing process of the product on a particular production line. The production of nanofibers takes place in air-conditioned production halls with a cleanliness class 8 according to ISO 14664. The production meets all sanitary regulations related to work safety, as well as requirements for fire protection and environmental protection.

Nanovia is certified according to the following systems:

EN ISO 9001:2009 Quality management system

EN ISO 14001:2008 Environmental management

OHSAS 18001:2008 Occupational safety and health management system

Analytical activities

Nanovia has a well-equipped laboratory for evaluation of parameters and quality of nanofiber materials, or other filter materials and media.Nanovia offers analytical activities enabling the use of these devices to external entities (research organizations and industrial companies) as well.

- Scanning electron microscope VEGA 3 SEM enables the evaluation of material structure and measurements of fibre diameters.

- TEXTES FX 3300 device for measuring the permeability and pressure drop of a filter medium

- TOPAS PSM 165 FS device for measuring the bubble point values

- Automatic filter tester TSI CertiTest® 8127 – for testing respirators (EN 143) and filter media

- PALAS MFP 2000 – testing of filter materials (EN 779) and filter media